The History of Stainless Steel

Stainless steel has only been around for about 100 years. In that relatively short time—compared to other metals—it has revolutionized so many areas of our lives that it’s hard to image. In fact, most people likely aren’t aware of what stainless steel made possible and how different life was before it.

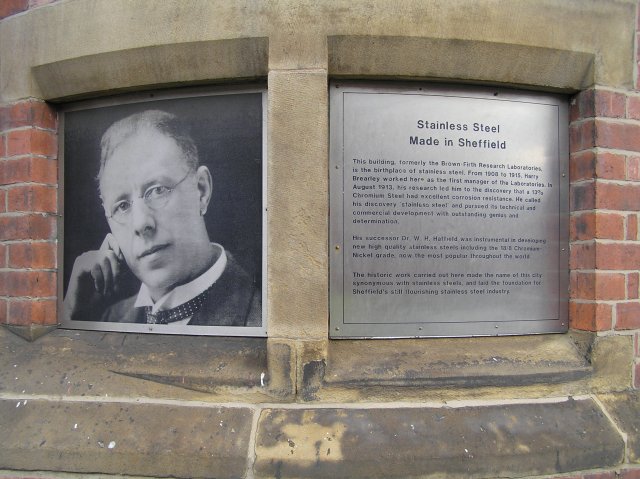

Harry Brearley

Harry Brearley grew up poor, even by the standards of the late 19th and early 20th Centuries. He took work in a chemical lab as a bottle washer, but washing bottles ended up getting him much more than a paycheck. Harry Brearley had an interest in metallurgy and he studied it intensely during his youth. As he progressed in his mastery of the subject, he became more adept and more interested until he finally started his own laboratory.

In around 1912, he started to experiment with a metal called chromium. He was interested in the problems characteristic of weapons of the age. Those weapons easily fouled and they tended to lose their accuracy and reliability as they heated up during use. When cartridges are set off, they release hot gasses and solids down the barrel, which leads to this fouling. Harry Brearley realized that chromium steel might hold the answer to this age old problem.

He started combining chromium with steel at approximately 12.8 percent chromium. This was the first steel produced that resembled the stainless steel we know today. His steel was less than 1 percent carbon, which is less than many modern stainless steels, but this steel did provide the foundation for what was to follow: a revolution in metallurgy.

Harry Brearley was not really trying to create stainless steel; he was trying to solve a problem with firearms. What he created, however, went far beyond that in its potential. He was aware of how useful this metal could be for cutlery and, in fact, most kitchen knives are made out of stainless steel, as it doesn’t rust away the way that high-carbon blades tend to if they’re not cared for almost constantly.

The Impact

Over the last 100 years, stainless steel has only gotten better. Other materials have been alloyed with it and have made it even better. There are many different types of stainless steel on the market, with varying percentages of nickel, chromium and other materials added in to change their properties. Today, stainless steels such as VG-10 can take the razor edge that carbon steel is known for but hardly ever develop even a spot of rust or a bad stain. This material is used in machete blades and other hard working tools in forms that do not sharpen to quite the same edge but which are virtually indestructible during normal use.

In Industry

Modern industry would be much different without stainless steel. From medical devices to refineries, it’s found everywhere. It holds up to the worst damage that chemicals can throw at it. It’s even vital in maritime applications, where most materials rot away from the harsh salt air.

There is hardly anywhere that you won’t see stainless steel in use these days. In your kitchen, in your computer and in your cell phone. It’s one of the most versatile and useful materials ever invented and it keeps getting better all the time. As one final bonus, the USA can proudly say that it still makes the best stainless steel in the world. The inspection process and the quality standards are exceptionally high and there is nowhere you’ll find a better quality product or the level of innovation that goes into improving that product that you will in the US stainless steel industry.

Image Credit: Wikipedia (Harry Brearley)